Alternative Marine Power (AMP)

|

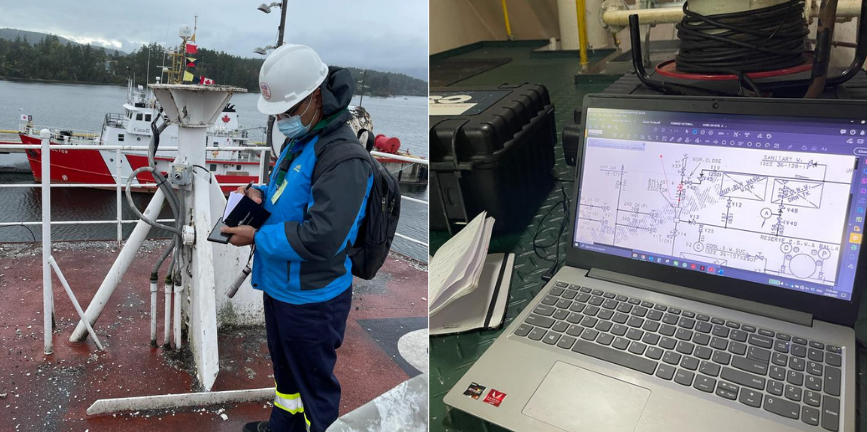

Alternate Marine Power (AMP) is an effective solution to reduce air pollution from ships, especially while they are in port. Due to strict environmental regulations from organizations such as the IMO, the European Union, and the US government, ship owners are required to reduce emissions and adopt cleaner technologies. Albion Marine Solutions supports this transition by offering AMP solutions that help vessels operate in a more environmentally responsible manner. When a ship is alongside in port, its main engines are shut down, but auxiliary engines continue to run to supply power for lighting, communication, HVAC, and hotel services. These engines burn fuel and release harmful emissions that affect air quality and human health. AMP allows ships to connect to shore-side electricity so that auxiliary engines can be turned off completely, eliminating emissions, noise, and vibration while in port. Albion Marine Solutions provides full support for AMP operations, including inspections, system checks, troubleshooting, cable connection and disconnection, power changeover, and reporting. With experience across major ports in Canada, the USA, Europe, and Asia, Albion ensures safe, reliable, and compliant shore power connections, even where technical challenges exist. By using AMP, ships can significantly reduce emissions such as SO₂, NOₓ, CO₂, and particulate matter, while also improving air quality in port areas. Albion Marine Solutions delivers AMP as a turnkey, cost-effective solution and continues to support clients through maintenance, training, commissioning, and worldwide service, ensuring long-term and sustainable operation. |

|

Albion Battery Energy Storage System (BESS)

A Battery Energy Storage System (BESS) represents a class of advanced rechargeable battery solutions designed to store electrical energy from various sources and release it in a controlled and strategic manner to meet specific operational requirements. In marine applications, BESS plays an important role in improving energy efficiency, enhancing operational flexibility, and reducing environmental impact.

A marine BESS can be charged using electricity generated from a vessel’s shaft generator, shore power connection, or renewable energy sources such as wind and solar power. Intelligent battery management software uses advanced algorithms to coordinate energy production, storage, and discharge. Computerized control systems continuously evaluate operating conditions to determine when energy should be stored and when it should be released to support vessel operations.

The Power Conversion System (PCS) manages the transfer and conversion of electrical power between the vessel’s electrical network and the battery system. It ensures safe and efficient charging of the batteries and enables controlled discharge when power is required. The batteries store energy when it is available and deliver it when demand increases, improving overall power system stability.

Integrating a BESS is particularly beneficial during cargo handling operations, where vessels experience high and fluctuating power demand. The system provides reliable and stable electrical support, reducing the load on auxiliary generators and ensuring uninterrupted cargo operations.

|

|

BESS also supports emission reduction by minimizing generator running hours and optimizing fuel consumption. Vessels with high emission profiles can significantly lower their environmental footprint, helping owners meet sustainability targets and comply with increasingly strict environmental regulations.

In addition, many ports—especially in Western countries—enforce stringent emission standards for vessels during port entry and berthing. A BESS enables ships to comply with these requirements, allowing continued access to regulated ports without operational restrictions.

Finally, the use of a BESS contributes to improved Carbon Intensity Indicator (CII) performance. By enhancing energy efficiency and reducing unnecessary fuel consumption, BESS helps vessels achieve better CII ratings, supporting regulatory compliance and long-term operational sustainability.

.png)