|

Crew training in the operation and maintenance of the shipboard equipment and systems is compulsory under the Standards of Training, Certification and Watch (STCW-95), and other international conventions and national legislations.

Albion Marine Solutions develops vessel- and equipment-specific crew training manuals and computer-based training programs. Training programs are customized to a client’s specific requirements. Our expert team has completed numerous training sessions aboard vessels. |

|

|

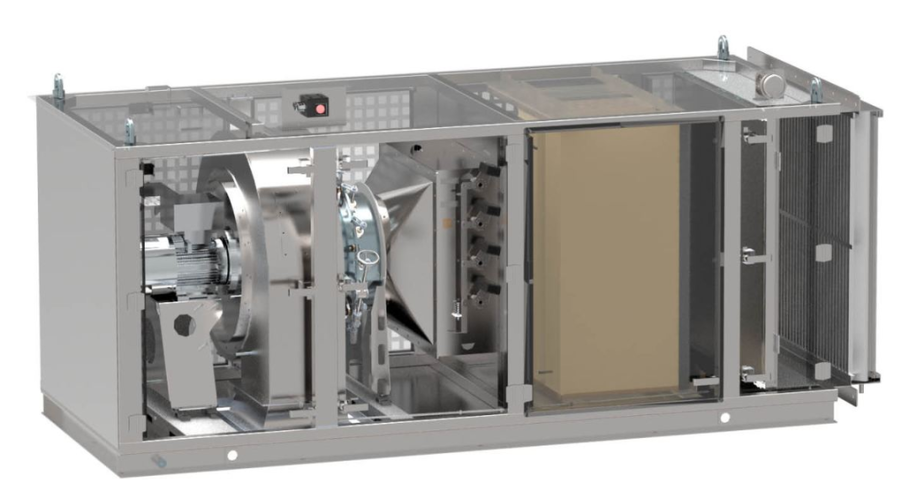

Our team can also prepare a maintenance program for newly installed equipment. The maintenance program includes OPEX cost projections, a maintenance schedule checklist, a detailed list of the installed components along with the critical and other spare parts. The maintenance program is designed to satisfy Class requirements and is customized for the client’s maintenance policies and standards. Our team has extensive experience with various models of Planned Maintenance Systems (PMS), including DNV GL, NS5, AMOS, RAST, Neptune, InfoShip, TM Master, GL Shipmanager, Maximo, BASSnet, Star IPS and TeoMaki. We can develop and manage a complete Planned Maintenance System and Dry Dock Management System.

|

|

|

Albion Marine Solutions Ltd. provides flexible, cost-effective maritime vessel operations with a qualified marine workforce that can work in all conditions. Our team provides comprehensive, expert and responsive in-service support for maritime assets, delivering efficient vessel operations with optimal performance. We deliver testing, analysis, support and emergency services to clients to maintain operational efficiency and performance. The main aim of any maintenance plan on a ship is to get the maintenance and repair work done in the least possible time at minimum costs. Our team prepares a maintenance plan to ensure that the machinery aboard a vessel maintains required standards of operation and safety. A maintenance plan constitutes an imperative element of a ship’s routine operations and is an integral component of the vessel’s maintenance mechanisms. In establishing a maintenance plan, several aspects should be taken into consideration, starting with the International Safety Management (ISM) code to the specifications and guidelines issued by the manufacturers of the machinery. In developing each vessel’s maintenance plan, Albion Marine Solutions takes into consideration: • International Safety Management (ISM) code requirements • Manufacturer-issued specifications and guidelines • Equipment history (including previous defects, failures, damage, and remedial actions) • A vessel’s age • Critical equipment and systems • Maintenance intervals • Possible consequences of failed or failing equipment on the vessel’s safe operation

A systematic procedure is established that forms an integral part of a ship’s planned maintenance system. For inspection purpose, checklists are often used to ensure that the inspection, test, and maintenance are each performed according to the ISM code requirements, manufacturer guidelines and the client’s specifications. Albion Marine has a worldwide network offering a wide range of engineering and technical services to ensure prompt response in various locations.

|

|