Albion Marine Solutions Ltd. is committed to providing robust, cost-effective technical services to various industry clients, including ship owners and operators, charterers, underwriters, protection, indemnity mutual insurance associations (P&I clubs), law firms, and flag states. Our client assistance extends beyond initiatives to improve operational integrity. We support our clients with a comprehensive approach throughout an asset’s lifecycle. With strong global expertise and experience, we are increasingly involved in decommissioning aging assets. We likewise provide offshore operators with end-to-end asset management solutions. Our service is based on our technical capabilities in establishing asset integrity management and risk modeling throughout a project’s lifecycle.

Ultrasonic Thickness Measurement (UTM)

Albion Marine Solutions Ltd provides comprehensive Ultrasonic Thickness Measurement (UTM) services to assess steel thickness, corrosion wastage, and the overall structural integrity of Ships and marine structures. Our UTM services are carried out strictly in accordance with IACS Unified Requirements (URs), applicable Classification Society Rules, and relevant IMO guidelines, supporting continued class compliance and the safe operation of vessels throughout their service life.

|

Regulatory & Technical Compliance

Albion’s UTM surveys are performed in alignment with, but not limited to, the following standards and regulations:

- IACS Unified Requirements (UR Z, UR S, UR W, as applicable)

- Classification Society Rules, including DNV, ABS, LR, BV, RINA, NK, IRS, and CCS

- IMO Instruments, including the Enhanced Survey Programme (ESP) Code, Condition Assessment Scheme (CAS), and relevant IMO Resolutions

- Flag State and Port State Control (PSC) requirements, where applicable

All measurements are obtained using Class‑approved and calibrated ultrasonic thickness measurement equipment, ensuring accuracy, traceability, and full acceptance by attending Class Surveyors.

Scope of UTM Services

Albion undertakes UTM surveys for both as‑built thickness verification and in‑service residual thickness assessment, including the following:

Structural Components

- Hull shell plating (side shell, bottom shell, bilge areas, and keel)

- Main deck, weather deck, and internal decks

- Longitudinals, transverse frames, girders, web frames, and stiffeners

- Bulkheads (watertight, oil‑tight, and non‑watertight)

- Hatch coamings, tank tops, stools, foundations, and structural insert plates

Tanks & Enclosed Spaces

- Ballast water tanks

- Cargo tanks (crude oil, product, chemical, and LNG/LPG containment structures, where applicable)

- Fuel oil, diesel oil, lubricating oil, and freshwater tanks

- Void spaces, cofferdams, and double‑bottom tanks

|

|

Piping & Miscellaneous Structures

- Cargo, ballast, and service pipelines

- Structural brackets, supports, and attachments

- Critical and corrosion‑prone structural members

Advanced Assessment

- Corrosion mapping and wastage trend analysis

- Identification of areas below Class minimum allowable thickness

- Technical support for steel renewal planning and repair specifications

Survey Attendance & Applications

Albion provides UTM attendance, measurement, and reporting support for:

- Annual Surveys

- Intermediate Surveys

- Special / Renewal Surveys

- Pre‑Docking and Dry Dock Surveys

- Condition Assessment Scheme (CAS) for ageing tankers

All UTM reports are prepared and formatted in accordance with Classification Society requirements, enabling efficient review and acceptance by Class Surveyors.

Vessel & Asset Types Covered

Albion’s UTM services cover a wide range of marine assets, including:

Commercial Vessels

- Bulk Carriers

- Oil Tankers (Crude & Product)

- Chemical Tankers

- LNG / LPG Carriers

- Container Vessels

- General Cargo Ships

- Ro‑Ro and Ro‑Pax Vessels

- Car Carriers

Specialized & Support Vessels

- Offshore Support Vessels (OSV)

- Anchor Handling Tug Supply (AHTS) Vessels

- Platform Supply Vessels (PSV)

Government & Naval Vessels

- Coast Guard vessels

- Naval auxiliaries

- Patrol vessels and other special‑purpose ships

Personnel & Equipment

- Certified, Qualified and experienced UTM inspectors with proven familiarity with Class survey requirements

- Equipment operated by certified personnel with documented competence and training

- Class‑approved ultrasonic thickness gauges with valid calibration certificates

- Proper surface preparation, repeat measurements, and verification practices to ensure data reliability

Latest Project and Scope of work

- Ro-Ro/Passenger Ship- 35-Year DNV Survey

- External Hull (Underwater and Above Water)- includes – Shell Plating, Bottom plating, keel plate, Bilge Plate, Rudder, Propeller Shaft brackets, Thruster tunnel and sea chest and grids.

- Internal Hull Structure (Within Ballast Tanks, Void Spaces, and Cargo Holds) includes - Tank Top Plating, Longitudinal and Transverse Framing, Tank Boundaries

- Weather Decks and Superstructure - includes - Exposed Freeing Ports, Deck Framing, Knuckle Points, Hatch Corners and Openings, Panting Beams and Stringers, Car Deck, Vehicle Deck, Ro-Ro Ramps / Stern Doors.

Deliverables

Albion provides clear, structured, and Class‑ready UTM reports, including:

- Defined measurement locations and recorded thickness values

- Comparison of original (nominal) and residual thickness

- Percentage wastage calculations

- Identification of critical, suspect, and corrosion‑affected areas

Reports are readily acceptable to Class Surveyors, Vessel Owners, Operators, and Shipyards.

Why Choose Albion Marine Solutions

- Proven experience supporting Class and statutory surveys across vessel types

- Strong understanding of IACS Unified Requirements and Classification Society rules

- Reliable and repeatable measurements with full traceability

- Efficient onboard execution with minimal disruption to vessel operations

Albion Marine Solutions Ltd delivers technically sound, Class‑aligned Ultrasonic Thickness Measurement services that support structural integrity, corrosion control, and continued compliance of ships and marine assets.

Non-Destructive Testing (NDT)

Albion Marine Solutions provides a complete range of Non-Destructive Testing (NDT) services to support the safety, structural integrity, and regulatory compliance of marine, offshore, and industrial assets. Our NDT services are carried out by qualified and certified inspectors using industry-recognized techniques and calibrated equipment, supporting both new-build and in-service vessels.

Non-Destructive Testing allows for the identification of surface and internal defects without affecting the usability of the inspected component. Through the application of established NDT methods, Albion Marine Solutions detects cracks, corrosion, weld discontinuities, and material degradation at an early stage, helping operators reduce operational risk, avoid unexpected failures, and extend asset service life.

Our NDT capabilities cover a full range of inspection techniques, including visual inspection, ultrasonic testing for thickness measurement and internal flaw detection, radiographic testing for weld and casting evaluation, magnetic particle testing for surface and near-surface defects in ferromagnetic materials, dye penetrant testing for surface-breaking flaws, and eddy current testing for conductive materials and corrosion detection. Each method is selected based on project requirements, class rules, and applicable standards.

Albion Marine Solutions delivers NDT services across a wide range of applications such as hull structures, welded joints, pipelines, pressure vessels, storage tanks, machinery components, offshore structures, and retrofit or repair projects. All inspections are performed in accordance with relevant classification society requirements, IMO regulations, and international codes and standards.

By engaging Albion Marine Solutions, shipowners and operators benefit from early defect identification, improved safety and reliability, reduced maintenance costs, and clear technical reporting to support repair, retrofit, and life-extension decisions. Our practical, engineering-focused approach ensures inspection findings are directly aligned with operational and project objectives.

Ship Structure Repair Plan

Albion Marine Solutions provides integrated Ship Structure Repair Plan engineering and design services to support the safety, structural integrity, and regulatory compliance of existing vessels. Our solutions are developed for a wide range of ship types and focus on hull structure repairs, system improvements, and regulatory upgrades while minimizing vessel downtime.

Each Ship Structure Repair Plan is developed through detailed engineering assessments and class-approved methodologies to ensure full compatibility with the vessel’s existing configuration. Our multidisciplinary engineering team evaluates the impact of proposed repairs on hull strength, stability, and system interfaces, ensuring that all modifications maintain structural reliability and operational performance.

Albion Marine Solutions supports emission-related modifications where structural adaptations are required, including the integration of scrubber systems, ballast water management systems, and energy-efficient propulsion improvements. In addition, our services cover hull steel renewal, structural reinforcements, and upgrades to machinery foundations, piping systems, and automation interfaces.

Digitalization and monitoring solutions are incorporated where required to support structural condition monitoring, maintenance planning, and improved operational efficiency. These solutions enable shipowners to make informed decisions based on accurate condition data and engineering analysis.

From feasibility studies and 3D laser scanning to detailed engineering, class coordination, and onboard repair support, Albion Marine Solutions delivers end-to-end Ship Structure Repair Plan services. Our approach helps shipowners extend asset service life, manage repair scopes effectively, and achieve full compliance with international maritime regulations and classification society requirements.

|

|

|

|

|

|

|

Commissioning

During the construction phase of a project, it is essential to maintain control over the quality of the materials and services being procured. Equally crucial is ensuring that site conditions do not pose any kind of risk or delay to the start of construction. During any project, it is likewise critical to monitor actual progress against expected progress so that any potential issues are promptly identified and corrected. Albion Marine Solutions Ltd. offers highly skilled engineers with vast experience to assist with the commissioning of various systems.

Commissioning on site is nearly always done in the presence of the client and, if required, an official representative of a classification society. An essential aspect of the commissioning is the testing of capacity and functionality. Our qualified engineers conduct installations and commissioning worldwide and provide effective, feasible and comprehensive solutions to the challenges arising from any project.

|

|

|

Inspections and Surveys

Albion Marine Solutions Ltd. provides expert inspection and survey services to various shipping companies worldwide. A highly trained staff of professional marine engineers, captains, surveyors, and technicians is prepared to assist with:

|

- Pre-purchase and sale inspections

- Condition surveys

- Digital/3D surveys

- Insurance surveys,

- Damage and repair surveys

- Expert witness documentation/testimony

- Lightship surveys and inclining experiments

- Vessel loading and lashing surveys

- Inspection and site supervision

- Construction inspections

- Engine and machinery inspections

- Tonnage measurements calculations and consultations

- Deadweight audits

|

- Navigational audits

- MARPOL audits

- Safety management system audits

- Cargo operation audits

- Bridge resource management audits

- Engine room resource management audits

- Mooring operation audits

- Hazardous materials inventories

- Cargo tank inspections

- Cargo holds inspections

- Close up and drone inspections

- Measuring equipment validation verification

|

|

| |

Superintendency / Site Supervision

Experienced site supervision capability: Albion Marine Solutions has been involved in site supervision for: Construction repairs, conversions, and retrofits of various vessels, including FPSOs, FSRUs, bulkers, tankers, barges, and boats. Albion Marine has completed several supervision projects worldwide.

We have established a project team of maritime experts with extensive backgrounds in marine engineering, naval architecture, vessel surveys, and project management. Our superintendents are specialized in newbuilding supervision and have extensive experience in design/construction management, engineering design assistance, construction supervision: Outfitting, hull, mechanical, electrical and instrumentation, piping, coating, LNG, and offshore systems and are committed to providing the best newbuilding supervision service to the utmost.

|

|

Purchase and Sales Inspections

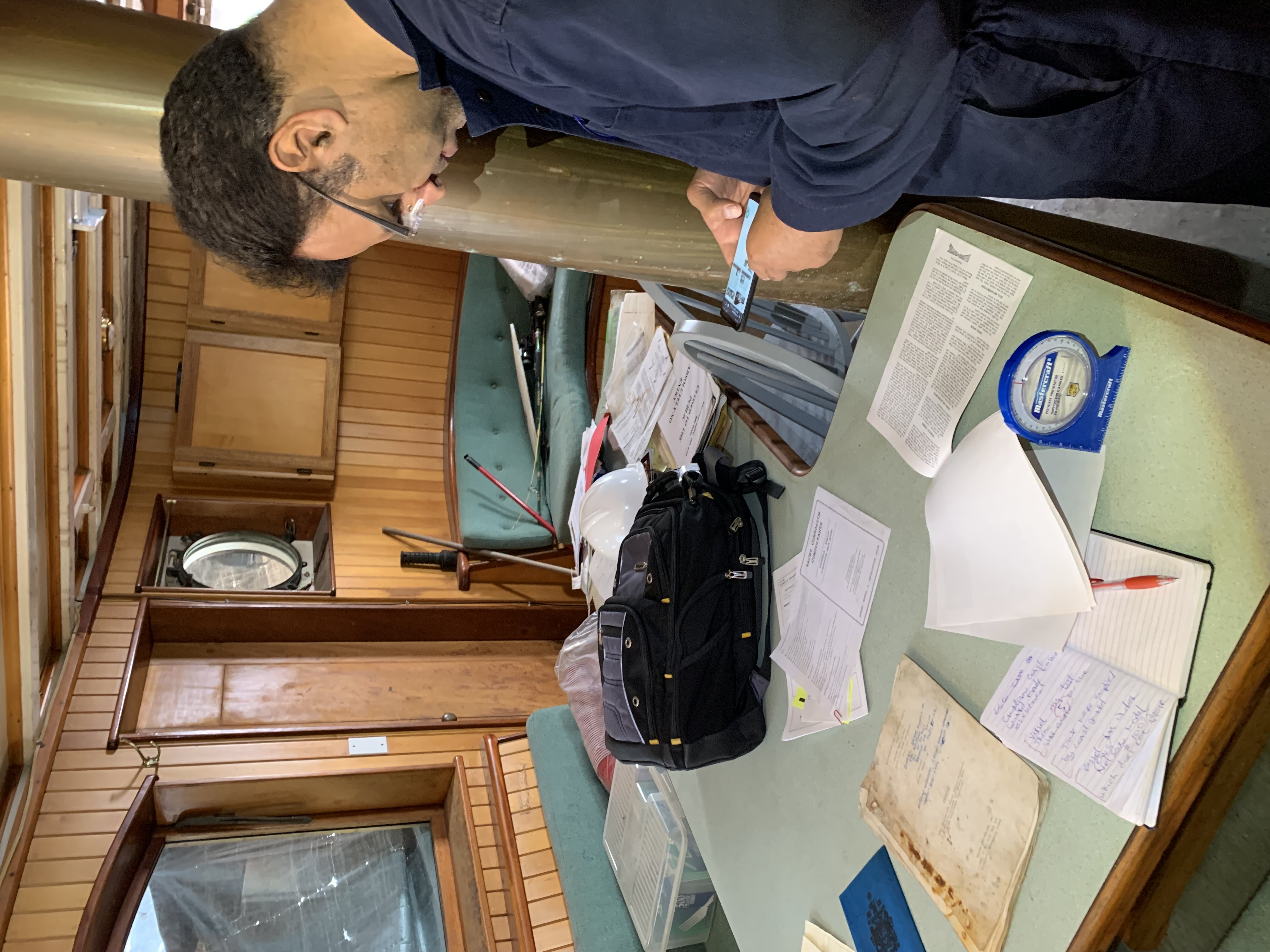

As a guaranteed independent expert, Albion’s team of surveyors can safeguard a client’s interests by conducting on-site purchase and sale vessel inspections. We help our clients to identify actual or potential safety and operational issues with a detailed report on a vessel’s condition. The vessel is thoroughly inspected using Engineering Model Configuration Inspection (EMCI) standards.

|

|

Riding Squads and Voyage Repairs

Albion Marine Solutions Ltd. carries out voyage repairs and sea-going maintenance, providing riding repair teams all over the world. Our team is composed by trained and certified fitters, welders, GRE fitters, electricians, skilled and trained Fitters for Main and Auxiliary engine major overhauls and technicians to ensure safe and efficient repairs and retrofits on board of the ships at sea or in ports. We carry out full range of mechanical, piping and steel work at anchorage or at berth.

Albion Marine has capability and expertise to take up voyage repairs onboard all types of the vessels. The voyage repairs are carried out onboard the vessels without hampering the routine operation of the vessels and thus no commercial loss for the clients. Albion can take up voyage repairs or work in the shipyard for new build and during routine dry-dock repairs with the Riding Squads.

|

|

Riding Squads Can Perform:

- Repairs and/or renewal of steel and/or GRE pipes,

- Fabrication jobs involving installation of ladder, stairs, access platforms, installation of lifting I-beam,

- Retrofitting of any equipment/s on deck, engine room and accommodation

- Major overhaul of main engine and auxiliary engines

- Repairs of auxiliary machinery – viz. winches, windlass, deck cranes, various types of pumps, air compressors etc.

|

|

Tender Support

The tender phase of your project is a time consuming and resource intensive task. Albion Marine Solutions tender support ensures an accurate tender phase with expert tender documentation preparation, analysis, and negotiation. We work with our clients to coordinate the tender process and meet deadlines

Our team of professionals helps ensure an accurate tender procedure to prepare and negotiate all project bids.

|

|

Albion Marine can either help create the content for the entire document, including the commercial elements, or work with content you provide, making sure that it is complete and meeting the tender guidelines.

Albion Marine Solutions can help you with:

- Define a strategic plan and choose the right bidders

- Ensure all goods and services meet the quality assessment and are in full regulatory compliance

- Ensure successful negotiations

Our tender support service includes: Document review, Preparation of documentation, Bid evaluation and negotiation, Project planning, Resource planning and Tender procedures

To discuss how we can offer you extensive support to ensure a successful tender phase, contact us today.

|

|

Prefabrication

We specialize in the prefabrication of piping and steel work for the installation of equipment in order to reduce a refit time, while at sea, alongside or in dock. Complete work packages, including cabling, fittings, prefabricated piping, foundations, equipment, and associated hardware, are assembled, and shipped worldwide.

|

|

Maintenance Optimization

Our maintenance planning specialists have extensive background in implementing and improving the Planned Maintenance Programs in order to prevent breakdowns and reduce OPEX.

|

|

Condition Assessment Survey

- A precise, reliable, intuitive drone inspection of interior spaces

- Real-time HD feed to the surveyor or the ship owner

- A spherical carbon-fiber cage that protects the drone propellers to facilitate confined-area use

- Repeatedly tested reliability in terms of capability to pass through vessel portholes

- Photogrammetry software for a 3D imaging option

- Combined use with LIDAR V1 & HF1 technology for on-board processing and real-time analysis

- Simultaneous Localization and Mapping (SLAM) that facilitates accurate 3D mapping in GPS-denied environments, such as within interior spaces, underground, or near large structures.

- 3D modelling of the inspected space

- Locating, quantifying, and measuring faults precisely

- A simpler way to spot faults than numerous time-consuming photo comparisons with an internal structures map

- Time and project cost savings

- Easier volume and dimensional calculations

|

|

|

Digital Twins

Albion Marine Solutions aims to provide new industry tools that will enable vessel brokers, project managers, and inspectors to remotely access vessels, saving them time and money while lowering the risk of unforeseen conditions and change orders.

A digital twin is a digital representation of a physical entity or framework. Data can be analyzed, and systems can be monitored by combining the virtual and physical worlds in simulations to avoid unintended consequences, reduce downtime, discover new opportunities, and even plan for the future. The technology underlying digital twins has evolved to include large objects such as machinery, buildings, and even ships.

|

|

Benefits of the Digital Twin in Shipping

- Fleet Optimization Through Virtual Ship Control System Transition

- Improving Port and Terminal Operations

- Situational awareness in terms of operational parameters

- Supply Chain Optimization from Start to Finish

- Increased Security Ensures Safety

|

|