Exhaust gas cleaning systems (EGCS), also known as scrubbers, are used to stop particulate matter and harmful air emissions, such as sulphur oxides (SOx) and nitrogen oxides (NOx), from being released from a marine engine’s combustion exhaust gases. EGCS provide a reliable, efficient, economical alternative to using distillate or low sulphur content fuels.

Albion Marine Solutions offers the expert services of its professional team to plan, execute and support vessel retrofits for the installation of scrubbers, selective catalytic reduction (SCR) systems, and exhaust gas recirculation (EGR) systems. Our team does so with a parallel management of the operational and technological risks by sourcing the most cost-effective, reliable solutions from both a capital expenditure (CAPEX) and future operating expenditure (OPEX) perspective.

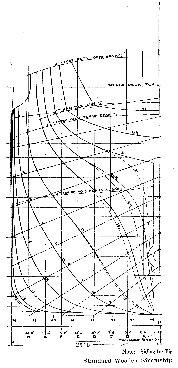

Albion Marine Solutions has designed and developed a number of EGCS conversions for domestic and international trade vessels.

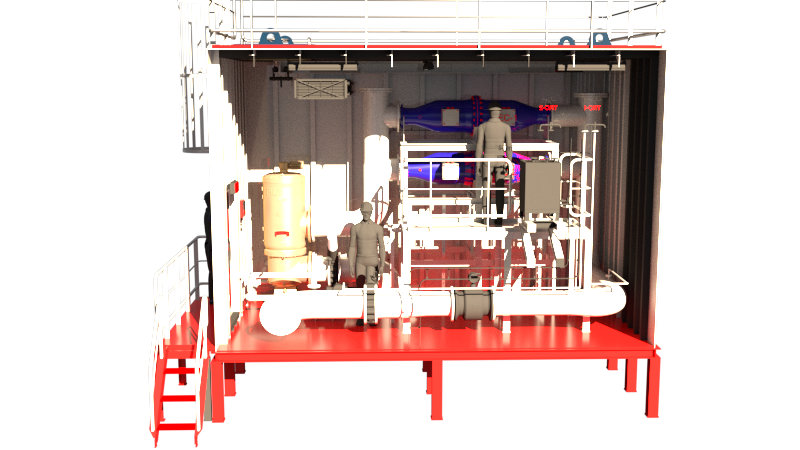

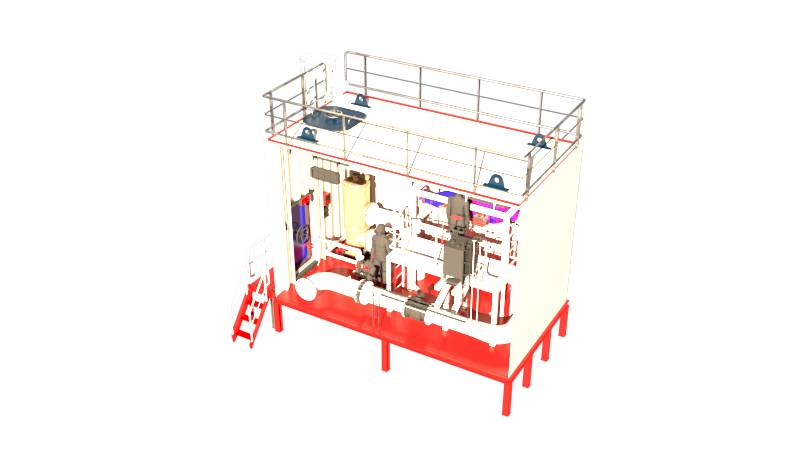

With the support of the Government of Canada, Albion Marine Solutions has developed its own proprietary design of the Advanced Air Emission Abatement Technology Floating Unit. The unit is designed to capture SOx, NOx, carbon, greenhouse gases and particulate matter released from the exhaust flue of oceangoing vessels calling at Canada’s major ports.

Albion Marine Solutions Ltd. is an Associate Member of the Exhaust Gas Cleaning System Association. Our team has direct experience in ship operations and conversions and makes it a priority to stay thoroughly familiar with all commercially available emission abatement systems and their related technologies.

Our services include:

- Technical and commercial feasibility studies

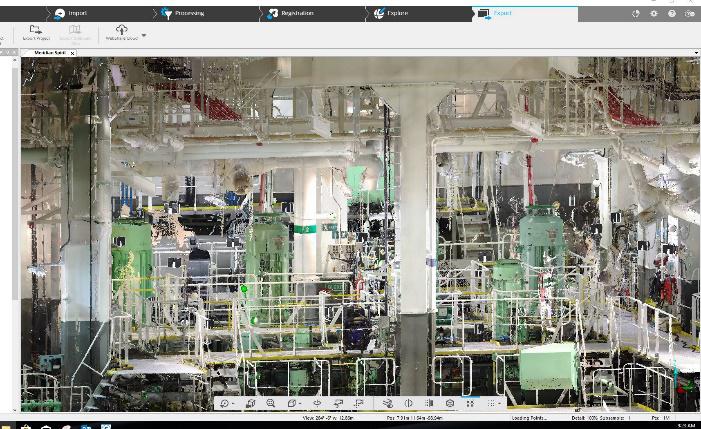

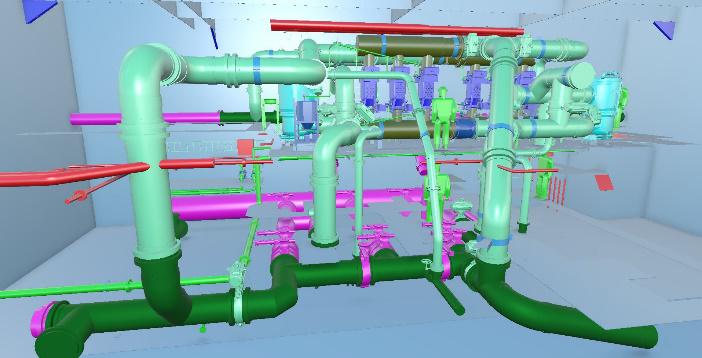

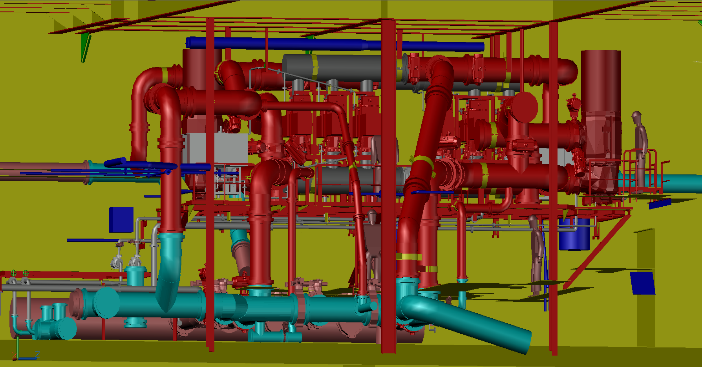

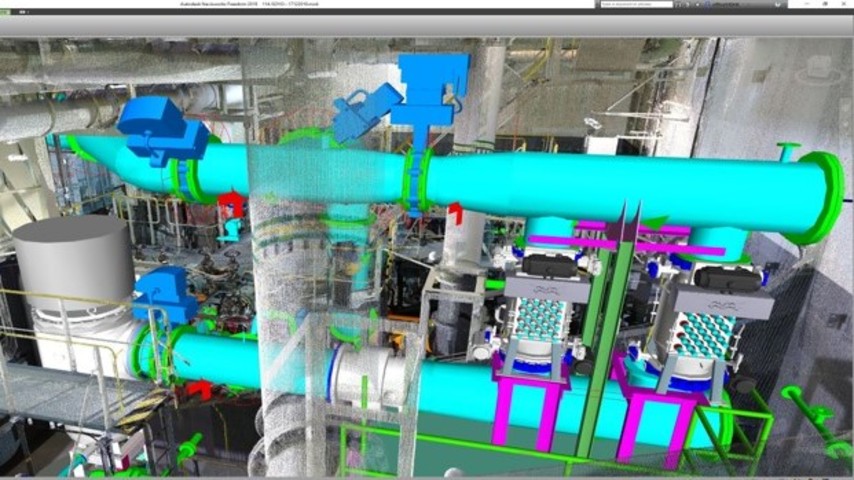

- 3D scanning and modeling

- Basic and detailed designs

- Procurement and prefabrication services

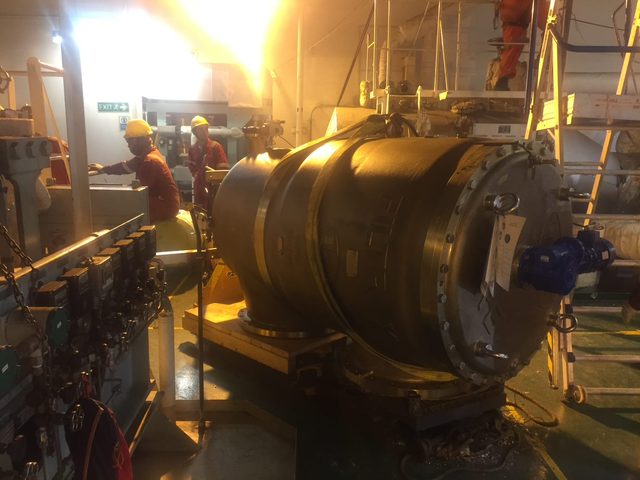

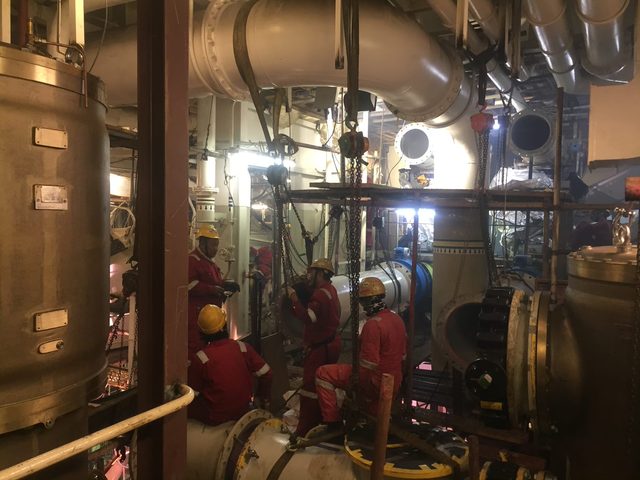

- Retrofits by riding crew and at anchorage

- Yard supervision

- Troubleshooting and repairs

- Instrument calibration and verification services

- Sensor exchange programs

- Crew training

Associate Member of Exhaust Gas Cleaning Systems Association

|

|

|

|

|

|