Main Engine OverhaulAlbion Marine Solutions Ltd, provides a highly efficient ME overhaul services designed to restore peak performance, improve fuel efficiency and extend the service life of the main engine. With experienced engineers, OEM-compliant procedures and strict quality control, we deliver overhauls you can trust- whether planned maintenance or emergency repair. We specialize in MC, ME-C, ME-B engines, providing complete mechanical & electronic overhaul solutions for marine engines across all vessel types.

|

|

Scope of ME Engine Overhaul

|

Mechanical Overhaul

|

Electronic & Control System

|

Why Choose Albion

- Reduced downtime - Efficient planning and execution to minimize off-hire time

- Enhanced Reliability - Early fault detection and correction action

- Fuel Efficiency Optimization - Precise calibration and tuning

- Safety & Compliance - Class and maker-compliant workmanship

- Transparent Reporting - Detailed service reports and recommendations

Auxiliary Engine Overhaul

Albion Marine Solutions Ltd, offers a comprehensive Auxiliary Engine Overhaul services designed to restore engine performance, improve reliability, and service life. Our experienced technical team ensures every overhaul is carried out in accordance with OEM standards and international standards.

Scope of Work

The overhaul includes complete dismantling, inspection, repair, and reassembly of the auxiliary engine and its associated systems. Major components are examined for wear, damage, and performance degradation, and replaced or refurbished as necessary.

|

Scope of Services

Testing & Commissioning

Key Benefits

|

|

Why Choose Albion

- Skilled engineers with extensive auxiliary engine experience

- Strict adherence to OEM guidelines and quality standards

- Quick turnaround with cost-effective solutions

- On-site and workshop overhaul capabilities

Pump Overhaul & Maintenance Services

Ensuring reliable pump performance under all operating conditions

Albion Marine Solutions Ltd. provides comprehensive technical services for overhaul, maintenance, and performance restoration of all types of marine and industrial pumps. Our services support shipowners and operators in maintaining system reliability, safety, and compliance with OEM specifications, classification society requirements, and Flag State regulations.

Our pump overhaul services are engineered to ensure mechanical integrity, hydraulic efficiency, and high equipment availability across all vessel operating profiles and trading areas.

Preventive Maintenance and Condition Assessment

Albion conducts planned maintenance, condition-based inspections, and detailed pump health assessments in accordance with OEM manuals, PMS requirements, and class standards.

Our service engineers evaluate pump condition using key technical parameters such as:

- Bearing condition and clearances

- Shaft alignment, run-out, and surface condition

- Seal and packing integrity

- Impeller wear, erosion, and cavitation damage

- Hydraulic performance indicators (pressure, flow, vibration, noise)

- Casing wear, corrosion, and structural integrity

Early identification of wear and degradation allows corrective actions to be implemented before failure, reducing downtime and secondary damage.

Pump Mechanical Overhaul and Repair

Albion Marine Solutions provides complete mechanical overhaul and repair services for all pump types, including:

- Centrifugal pumps (single-stage and multistage)

- Positive displacement pumps

- Gear and screw pumps

- Piston and plunger pumps

- Vertical and horizontal pumps

- Hydraulic and chemical dosing pumps

Typical overhaul scope includes:

- Complete dismantling with component identification

- Detailed visual and dimensional inspection of critical parts

- Shaft straightness and journal condition checks

- Bearing inspection, clearance measurement, and renewal

- Mechanical seal or gland packing replacement

- Impeller inspection, repair, or renewal

- Casing inspection for wear, corrosion, and cracking

- Replacement of worn components using OEM or class-approved spares

- Precision reassembly in accordance with OEM tolerances

Alignment, Testing, and Performance Verification

Following overhaul, pumps are subjected to:

- Shaft and coupling alignment checks

- Operational testing under load (as applicable)

- Verification of pressure, flow, and vibration levels

- Leak and integrity checks

Testing confirms that pumps meet operational and safety requirements prior to return to service.

Instrumentation and Measurement Support

Where applicable, Albion inspects and verifies pump-associated instrumentation, including:

- Pressure and temperature transmitters

- Flow indicators and switches

- Vibration and condition monitoring sensors

All measurements are carried out using calibrated instruments, with results documented for technical records and audits.

Documentation and Technical Reporting

Upon completion of pump overhaul services, Albion provides clear, audit-ready documentation including:

- Overhaul and inspection reports

- Measurement and clearance records

- Test and verification results

- Technical recommendations for continued operation

Reports are suitable for class surveys, Flag State inspections, PMS updates, and management review.

Why Choose Albion

- Class & OEM-Compliant Execution: All pump overhaul activities carried out under approved procedures in accordance with OEM manuals, classification society rules, and statutory requirements.

- Experienced & Certified Teams: Highly skilled technicians experienced in overhauling centrifugal and positive displacement pumps, trained in confined space entry, gas testing, and onboard safety practices.

- Advanced Tools & Performance Testing: Use of calibrated measuring instruments, precision alignment tools, hydraulic equipment, and pressure/performance testing arrangements to ensure reliable pump restoration.

- Safety, Quality & Environmental Focus: Strong HSE and quality control culture ensuring safe dismantling, inspection, reassembly, and proper handling and disposal of oils, spares, and worn components in compliance with environmental regulations.

- Global Marine Support: Flexible mobilization for pump overhauls at ports, anchorages, shipyards, and workshops worldwide.

Albion Marine Solutions Ltd ensures pumps are fully restored to OEM performance standards, minimizing breakdown risk, improving operational reliability, and supporting smooth class surveys and vessel operations.

Valve Overhaul & Maintenance Services

Ensuring reliable valve operation and system integrity under all operating conditions

Albion Marine Solutions Ltd. provides comprehensive technical services for overhaul, maintenance, and performance restoration of all types of marine and industrial valves. Our services support shipowners and operators in maintaining safe operation, system integrity, and compliance with OEM specifications, classification society rules, and Flag State requirements.

Our valve overhaul services are designed to ensure leak-tight performance, mechanical reliability, and long-term serviceability across all vessel systems and operating profiles.

Preventive Maintenance and Condition Assessment

Albion carries out planned maintenance, condition-based inspections, and detailed valve health assessments in accordance with OEM manuals, PMS requirements, and class standards.

Our engineers assess valve condition using key technical criteria such as:

- Seat and disc condition (wear, erosion, pitting)

- Stem straightness, surface finish, and thread condition

- Gland packing and sealing integrity

- Actuator performance (manual, pneumatic, hydraulic, electric)

- Torque, stroke length, and response time

- Body and bonnet condition (corrosion, cracks, deformation)

Early detection of degradation allows corrective actions before leakage, seizure, or operational failure occurs.

Valve Mechanical Overhaul and Repair

Albion Marine Solutions undertakes complete overhaul and repair of all common valve types, including:

- Gate valves

- Globe valves

- Check (non-return) valves

- Butterfly valves

- Ball valves

- Plug valves

- Pressure relief and safety valves

- Control and actuated valves

Typical overhaul scope includes:

- Complete dismantling and component identification

- Cleaning and inspection of internal components

- Seat lapping or renewal as required

- Disc, ball, or plug inspection and repair

- Stem inspection, straightening, or renewal

- Gland packing and seal replacement

- Actuator inspection, servicing, and functional testing

- Replacement of worn parts using OEM or class-approved materials

- Precision reassembly in accordance with OEM tolerances

Testing and Functional Verification

Following overhaul, valves are subjected to:

- Pressure testing (hydrostatic or pneumatic, as applicable)

- Leak tightness testing (seat and shell)

- Operational stroke and torque verification

- Functional testing of actuators and interlocks

Testing is carried out in accordance with applicable standards and class requirements to confirm safe and reliable operation.

Instrumentation and Actuation Support

Where fitted, Albion inspects and verifies valve-related instrumentation and control systems, including:

- Position indicators and limit switches

- Solenoids and control valves

- Pneumatic and hydraulic actuators

- Feedback and monitoring devices

All checks are carried out using calibrated instruments and approved procedures.

Documentation and Technical Reporting

Upon completion of valve overhaul services, Albion provides comprehensive, audit-ready documentation including:

- Overhaul and inspection reports

- Pressure and functional test records

- Clearance and acceptance criteria records

- Technical findings and operational recommendations

Documentation is suitable for class surveys, Flag State inspections, PMS updates, and safety audits.

Why Choose Albion

- Class & OEM-Compliant Execution: All valve overhaul activities performed in accordance with OEM guidelines, classification society requirements, and statutory regulations, ensuring full class acceptance.

- Experienced & Certified Teams: Skilled technicians experienced in overhauling gate, globe, butterfly, ball, check, and control valves, trained in confined space entry, gas testing, and hazardous area operations.

- Precision Tools & Functional Testing: Use of calibrated torque tools, lapping machines, seat grinding equipment, and hydrostatic/functional testing to restore tight shut-off and operational integrity.

- Safety, Quality & Environmental Focus: Strong HSE and quality control culture ensuring safe dismantling, inspection, reassembly, and responsible handling and disposal of lubricants, gaskets, and replaced components in compliance with environmental standards.

- Global Marine Support: Flexible service mobilization for valve overhauls at ports, anchorages, shipyards, and workshops worldwide.

Albion Marine Solutions Ltd ensures valves are restored to full operational integrity and leak-tight performance, supporting safe system operation, reliable isolation, and smooth class surveys.

Compressor Overhaul & Maintenance Services

Ensuring reliable compressed air and gas supply under all operating conditions

Albion Marine Solutions Ltd. provides comprehensive technical services for overhaul, maintenance, and performance restoration of all types of marine and industrial compressors. Our services support shipowners and operators in maintaining system reliability, safety, and compliance with OEM specifications, classification society rules, and Flag State requirements.

Our compressor overhaul services are engineered to ensure mechanical integrity, thermodynamic efficiency, and high operational availability across all vessel operating profiles and service conditions.

Preventive Maintenance and Condition Assessment

Albion conducts planned maintenance, condition-based inspections, and detailed compressor health assessments in accordance with OEM manuals, PMS requirements, and class standards.

Our service engineers evaluate compressor condition using key technical parameters such as:

- Suction and discharge pressure performance

- Operating temperature profiles and cooling efficiency

- Vibration levels and bearing condition

- Lubrication system performance and oil quality

- Valve plate, piston ring, and sealing condition

- Moisture carryover, and filtration

Early identification of wear, leakage, overheating, or contamination helps prevent unplanned shutdowns and secondary damage.

Compressor Mechanical Overhaul and Repair

Albion Marine Solutions undertakes complete mechanical overhaul and repair of all common compressor types, including:

- Reciprocating air compressors

- Screw compressors (oil-flooded and oil-free)

- Centrifugal compressors

- Scroll compressors

- Starting air compressors

- Control air and service air compressors

Typical overhaul scope includes:

- Complete dismantling with component identification

- Inspection of crankshaft, connecting rods, pistons, and cylinders

- Measurement and renewal of bearings, piston rings, and seals

- Inspection and servicing of suction and discharge valves

- Cooler inspection, cleaning, and pressure testing

- Lubrication system inspection and flushing (as required)

- Replacement of worn components using OEM or class-approved spares

- Precision reassembly in accordance with OEM tolerances

Testing and Performance Verification

Following overhaul, compressors are subjected to:

- No-load and full-load operational testing

- Pressure build-up and capacity verification

- Temperature and vibration monitoring

- Leak and safety device checks

Testing confirms safe operation, rated performance, and readiness for service.

Instrumentation and Control System Support

Where fitted, Albion inspects and verifies compressor-related instrumentation and control systems, including:

- Pressure and temperature sensors

- Safety and relief valves

- Automatic unloaders and control valves

- Alarm, shutdown, and interlock functions

All checks are carried out using calibrated instruments and approved procedures.

Documentation and Technical Reporting

Upon completion of compressor overhaul services, Albion provides comprehensive, audit-ready documentation including:

- Overhaul and inspection reports

- Measurement and clearance records

- Test and performance verification results

- Technical findings and maintenance recommendations

Documentation is suitable for class surveys, Flag State inspections, PMS updates, and technical audits.

Why Choose Albion

- Class & OEM-Compliant Execution: Compressor overhaul activities carried out in accordance with OEM manuals, classification society rules, and statutory requirements, ensuring full compliance with class and Flag State standards.

- Experienced & Certified Teams: Qualified technicians experienced in overhauling reciprocating and screw compressors for starting air, service air, and control air systems, trained in confined space entry, gas testing, and hazardous area operations.

- Precision Tools & Performance Testing: Use of calibrated measuring instruments, torque tools, alignment equipment, and pressure, leakage, and performance testing to restore compressors to OEM operating parameters.

- Safety, Quality & Environmental Focus: Strong HSE and quality assurance culture ensuring safe dismantling, inspection, reassembly, and compliant handling and disposal of oils, filters, and replaced components in line with environmental regulations.

- Global Marine Support: Flexible mobilization for compressor overhauls at ports, anchorages, shipyards, and workshops worldwide.

Albion Marine Solutions Ltd ensures compressors deliver reliable pressure and operational availability, minimizing downtime and supporting safe vessel operations and class approvals.

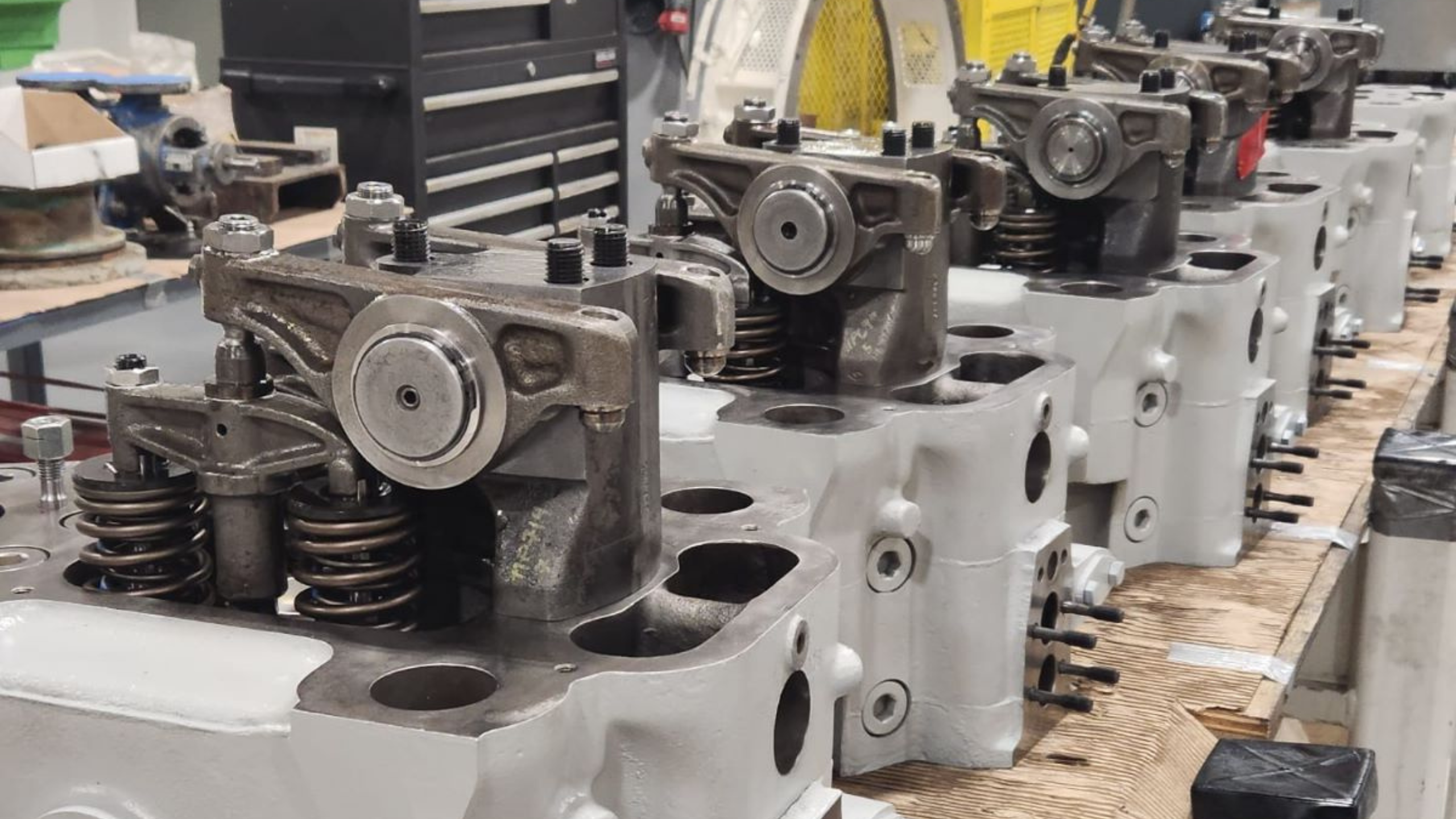

Albion Marine Solutions specializes in repairing and overhauling large-capacity diesel and marine engines.

|

Engine overhauls are typically performed according to the maker's maintenance schedule when an engine has accumulated significant operating hours and may have experienced reduced performance, increased oil consumption, or other mechanical issues. An overhaul can extend the engine's life and restore it to a like-new condition, saving the cost of a complete engine replacement and ensuring continued reliable operation. During an overhaul, the entire engine is taken apart, and each component undergoes meticulous scrutiny for any indications of wear, damage, or decay. Common parts that are examined or substituted during this overhaul process comprise: |

.png) |

|

Pistons: Inspected for wear, damage, or scoring. Replaced if necessary. Piston Rings: Checked for proper sealing and replaced if worn out. Cylinder Liners: Inspected for wear and replaced if required. Connecting Rods: Checked for bending, wear, or damage. Replaced if needed. Crankshaft: Checked for cracks, wear, and straightness. Reground or replaced if necessary. Bearings: Checked for wear and replaced if showing signs of damage. Cylinder Head: Inspected for cracks, warping, or valve seating issues. Repaired or replaced as needed. Valve and Valve Seats: Checked for wear and proper sealing. Replaced or re-machined if necessary. Timing Belt/Chain and Tensioners: Replaced to prevent future failures. Gaskets and Seals: Replaced throughout the engine to prevent leaks. |

|

|

At Albion Marine Solutions, we are experts in providing specialized engine overhauling services for all marine and diesel engines. Our skilled team excels in precision crankshaft grinding and repair and effectively addresses casting cracks and damages through advanced metal stitching and locking techniques. Our expertise extends to skillfully rebabbitting old bearings, restoring them to their original condition. With a primary focus on marine and auxiliary engine crankshaft repair, we have completed numerous jobs, building a solid reputation for delivering exceptional solutions in the industry. Albion Marine service engineers strictly adhere to the procedures for overhauling and repairing marine engines, following the guidelines specified in the manufacturer's maintenance manual. Our services encompass marine diesel engine repair and overhaul for all major manufacturers of 2-stroke and 4-stroke propulsion engines and auxiliary engines. |

.png) |

| Albion Marine's cost-effective Engine Overhauling services onboard vessels are powered by an expert team of highly skilled and experienced engineers who efficiently diagnose issues and perform accurate repairs. We prioritize high-quality parts and equipment, ensuring optimal engine performance and extended service life, thereby reducing the need for frequent repairs. Our on-site design support minimizes logistical costs and downtime, while strict adherence to regulations and industry standards ensures efficient and safe overhauling processes, mitigating the risk of additional expenses. |