|

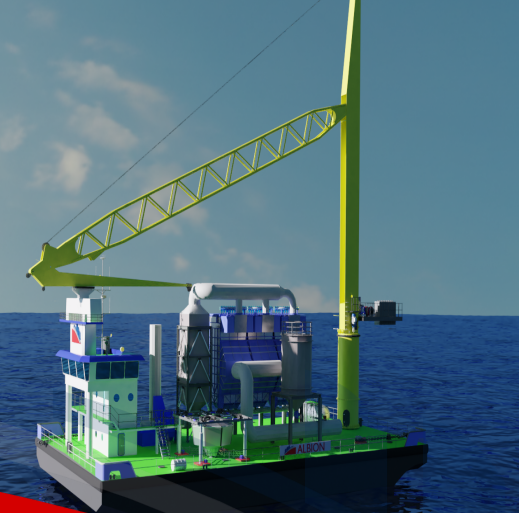

Onboard Carbon Capture and Storage: The International Maritime Organization (IMO) has intensified its commitment to reducing Greenhouse Gas (GHG) emissions from shipping, driving shipowners to adopt practical decarbonization measures. For existing vessels, a transition to zero-carbon fuels is often not economically viable. Onboard Carbon Capture, Utilization, and Storage (OCCUS) provides a proven and retrofit-friendly solution to reduce emissions, improve Carbon Intensity Indicator (CII) performance, and extend the operational life of assets while maintaining commercial viability. |

|

|

Carbon Capture and Storage (CCS) offers a flexible and cost-effective pathway to compliance with global and EU regulations, including the IMO CII framework under MARPOL Annex VI, effective from 1 January 2023. As CII thresholds tighten annually, vessels rated A, B, or C will remain more attractive to charterers and better positioned for long-term operation. CCS enables meaningful carbon reduction without repeated modifications to propulsion or fuel systems as regulatory phases evolve. Albion Marine Solutions delivers end-to-end CCUS and energy retrofit engineering for existing vessels, supported by extensive experience in ship modification design, gap analysis studies, and retrofit coordination. With proven expertise across multiple vessel types and retrofit systems, the team provides class-compliant, cost-effective solutions tailored to each vessel’s operational profile. Through strong engineering capability, project management, and global service reach, Albion Marine Solutions supports shipowners in achieving compliance, efficiency, and sustainability objectives. |

|

|

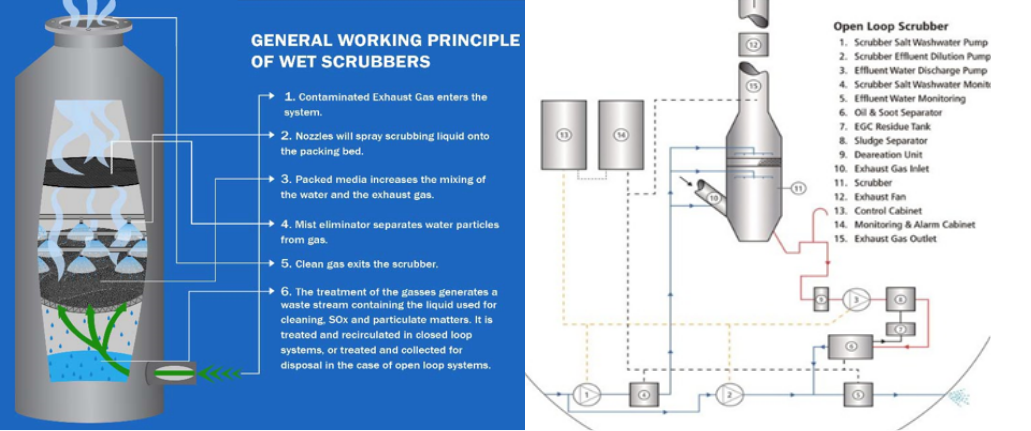

Exhaust gas cleaning systems (EGCS), also known as scrubbers, are used to stop particulate matter and harmful air emissions, such as Sulphur oxides (SOx) and nitrogen oxides (NOx), from being released from a marine engine’s combustion exhaust gases. EGCS provide a reliable, efficient, economical alternative to using distillate or low Sulphur content fuels. |

|

|

Albion Marine Solutions offers the experts services of its professional team to plan, execute and support vessel retrofits for the installation of scrubber, selective catalytic reduction (SCR) systems, and exhaust gas recirculation (EGR) systems/ Our team does so with parallel management of the operational and technological risk by sourcing the most cost effective, reliable solutions from a capital expenditure (CAPEX) and future operating expenditure (OPEX) perspective. Albion Marine Solutions has developed several EGCS conventions domestic and international trade vessels.

|

.png) |

|

Ensuring IMO Tier III Compliance Through Accurate Nox Testing: Industry-leading SCR NOx assessment and spot check services are offered to help shipowners and operators confidently meet the latest IMO emission requirements, including MEPC 83 updates and the 2025 Guidelines on Selective Catalytic Reduction Systems (MEPC.291(71)). The scope of service includes onboard verification of engine exhaust emissions, real-time performance validation of SCR systems under actual operating conditions, and testing fully aligned with MARPOL Annex VI and the NOx Technical Code 2008. Certified portable emission monitoring systems are utilized to ensure precise measurements and reliable compliance data. Backed by extensive experience in global fleet emission testing, these services are delivered by factory-trained engineers and certified marine professionals using state-of-the-art monitoring equipment. A strong track record with shipowners, managers, and OEMs worldwide ensures fast, dependable report delivery that supports class approvals, flag state acceptance, and port authority requirements. SCR NOx testing plays a critical role in achieving regulatory compliance, demonstrating environmental responsibility, and maintaining optimal engine performance. Through accurate verification and transparent reporting, shipowners gain greater operational confidence, improved efficiency, and long-term assurance that their vessels continue to meet evolving emission control standards while operating safely and sustainably at sea. |

|

|

Exhaust Gas Regulations (EGR) Albion Marine Solutions provides services to support vessel compliance with exhaust gas regulations imposed by international and regional authorities. Our solutions are designed to help ship owners and operators meet environmental requirements while maintaining safe, efficient, and cost-effective operations. Albion Marine Solutions supports compliance with IMO MARPOL Annex VI, including regulations governing sulphur oxides (SOₓ), nitrogen oxides (NOₓ), particulate matter, and greenhouse gas emissions. Our team assists with fuel compliance strategies, emission-reduction technologies, and documentation required for statutory and port state inspections. We offer technical advisory and engineering services for the evaluation, selection, and integration of exhaust gas control solutions such as exhaust gas cleaning systems (scrubbers), Selective Catalytic Reduction (SCR), Exhaust Gas Recirculation (EGR), and alternative fuel or hybrid power solutions. Each solution is assessed to ensure compatibility with vessel design, operational profile, and applicable Emission Control Area (ECA) requirements. Albion Marine Solutions also provides inspection, verification, and troubleshooting services to ensure continued compliance during vessel operation. This includes support during port state control inspections, performance monitoring of installed systems, and corrective action recommendations where non-compliance risks are identified. In addition, we assist ship owners in meeting regional and port-specific exhaust emission requirements, including shore power integration, auxiliary engine emission reduction, and operational measures to minimize emissions during port stays. Our services extend across the full project lifecycle, from feasibility studies and engineering design to commissioning, crew training, and ongoing technical support. Through our integrated and regulation-focused approach, Albion Marine Solutions enables vessels to achieve reliable compliance with exhaust gas regulations, reduce environmental impact, and maintain unrestricted access to global ports. |

|

|

SOx Scrubber Technologies: Albion Marine team has experience installing both the SOX scrubber systems wet scrubber that use water (seawater or fresh) as the scrubbing medium and dry scrubbers that use a dry chemical. Wet systems are further subdivided into open-loop systems that use seawater, closed-loop systems that use freshwater with the additions of an alkaline chemical, and hybrid systems that can operate in both loops and closed loops modes.

|

|

|

Project Planning and Management: Albion Marine Solutions provides well-organized project Management from the beginning to the completion of the project, an essential component of a successful retrofit project. Albion professionals project management team is well reliable and adhere to a cost-effective approach for successful project completion, including a time for interactions with third parties such as Class, Scrubber vendors, suppliers of OFE, logistics, technical procurement, etc.

|

.png) |

|

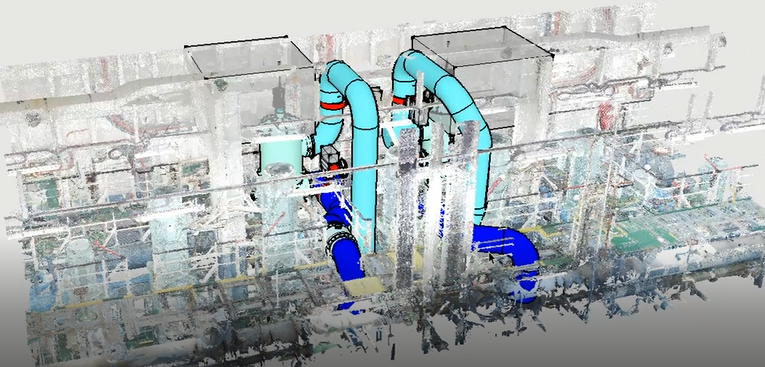

Ship Site Survey and 3D Scan: Albion Marine Solutions has an experienced Ship Site Survey team to onboard a vessel of any type to conduct an onboard survey. The survey team will use modern measuring and laser scanning equipment for their site survey to determine the exact location for any new equipment. The scanning team will identify all utility tie-in points for all systems under consideration.

|

|

| Feasibility Study: Selection of Scrubber System Wet ,Open and Closed loop Scrubber: Albion Marine Solutions provides its engineering expertise for selecting the scrubber system for installation onboard (retrofit) of the subject vessel. Albion Marine Solutions is very well familiar with most of the scrubber systems available in the market. Our key personnel have attended the training and production facilities of several major manufacturers. Also, our project personnel have hands-on experience with the integration and operation of several various scrubber systems. |  |

| Engineering Package (Concept Designs +Basic Engineering + Detailed Engineering): Albion Marine Solutions engineering work is an evaluation of the proposed Concept Design and its discussion with the stakeholders. The Concept Design will be developed on findings from the Ship Site Survey and the conclusions of the feasibility study. Then in Basic Engineering, the project team will deliver the generic and functional designs of the main components and systems, including piping, cabling, various foundations, etc. Lastly, The Detailed Engineering phase involves close coordination and synchronization among different engineering disciplines, with all in-house resources working interactively and progressively. |  |

|

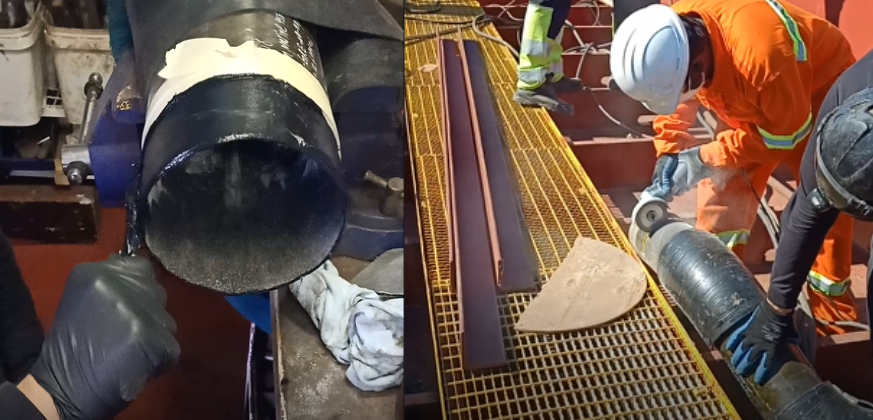

Prefabrication: Albion Marine offers a turnkey pre-fabrication package. Pre-fabrication is a critical component of retrofit activities. Albion Marine handles the entire pre-fabrication of the piping and foundations. Albion Marine would also provide all necessary valves, cables, and breakers and cover all the material acquisition costs, including freight.

|

|

|

Retrofits by Riding Crew and at anchorage: Albion Marine Solutions Ltd. provides trained and certified electricians, mechanics, pipe fitters and technicians to ensure safe and efficient repairs and retrofits on board of the ships at sea or in ports. The voyage repairs are carried out onboard the vessels without hampering the routine operation of the vessels and thus no commercial loss for the clients. Riding Squads are composed based on the nature of the job scope. Albion can take up voyage repairs or work in the shipyard for new build and during routine dry-dock repairs with the Riding Squads.

|

|

|

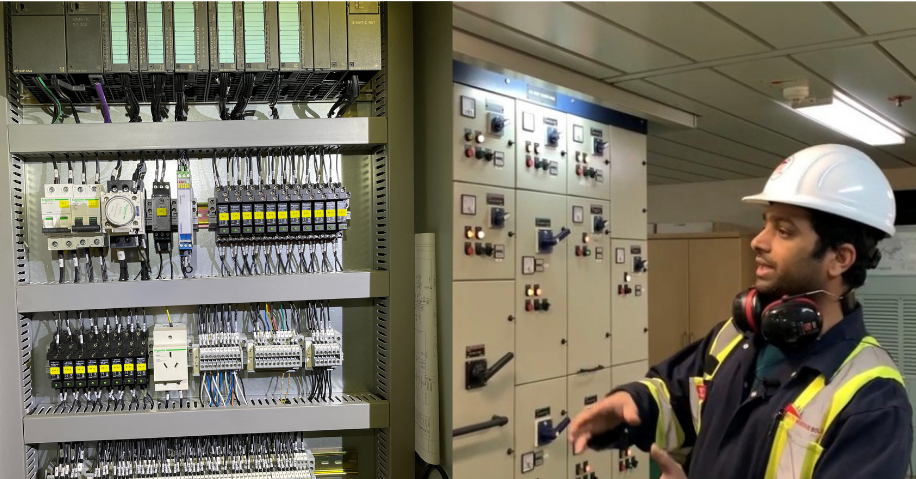

Commissioning: Albion Marine Solutions Ltd. offers highly skilled engineers with vast experience to assist with the commissioning of various systems. Commissioning on site is nearly always done in the presence of the client and, if required, an official representative of a classification society. An essential aspect of commissioning is the testing of capacity and functionality. Our qualified engineers conduct installations and commissioning worldwide and provide practical, feasible and comprehensive solutions to the challenges arising from any project.

|

|

| Training: Albion Marine Solutions provides training in scrubber maintenance and chemical handling. Our training covers system design and function, governing documents, operation, maintenance, and troubleshooting. Training can take place at customer sites. The well-trained crew who understands the system and regulatory issues will increase the lifetime of the machinery, reduce OPEX, and, crucially, lower the risk of non-compliance. Training can also prevent scrubber downtime should the crew misread or misunderstand the regulations.

|

|

|

After Sales Support : Albion Marine Solutions offers a full range of class, certification and verification services to support the proper installation and commissioning. Our team of experts can help you at any scrubber installation and operation stage. Albion Marine can also provide a lifecycle cost analysis that compares the economic impacts of the various fuel and associated equipment options to better inform our clients about the selection process. Albion Marine Solutions can help you make the right decisions for your fleet. After Sales Services :Complete Health Check (Semi-annual), Detailed Checklist- based inspection by maker trained personnel, No infringement with any maker. Does not involve proprietary software checks, covers structural, mechanical, and electrical maintenance scope, IAS, and system integration checks, including electrical cabling issues, Comprehensive health check report provided at the end with issues, recommendations, and photos. |

|

|

Sensor Exchange Calibration Program: Calibration of all sensors as per Maker’s manual, Maker- certified calibrated sensor is installed while the old sensor is sent to the sensor maker’s calibration facility and stored with AMS, involves all commonly used sensors such as pH sensor, pAH probe and turbidimeter and Sensor exchange/ replacement/ calibration – entirely managed by a dedicated Albion Marine Project Manager. |

|

Sample Projects

|

|

|

|